Safe by Design

Crown forklifts are designed with safety in mind. We aim to help you maintain a safe operation with equipment designed around your operator.

Seat Restraints

All Crown sit-down rider counterbalance models incorporate restraint systems designed to help keep the operator in the running lines of the lift truck in case of tip over. These restraints have proven to reduce injuries if properly utilized and maintained.

To accommodate various application and operator needs, Crown has various seat and restraint system options available for current Crown models. These include suspension seats and hip restraint systems.

Stand-up Rider Entry Bar

All stand up rider counterbalance and reach trucks include an entry bar at the opening to the operator compartment. This feature has been standard equipment since 1998. If the bar is depressed, an alarm will sound a warning and travel speed is reduced. The bar is designed to keep operators from operating the lift truck with their foot resting outside the running lines of the lift truck.

The entry bar can be added to some earlier models of stand-up riders.

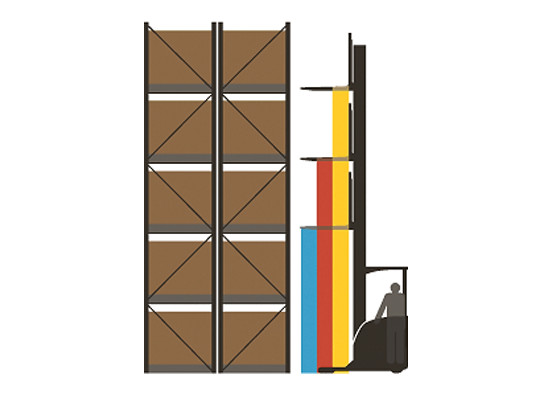

Stand-up Rider Posts and Extensions

All current Crown stand-up rider counterbalance and straddle lift trucks have backrest extensions that are 1460 mm from the floor in the area behind the operator. Third corner posts are also standard.