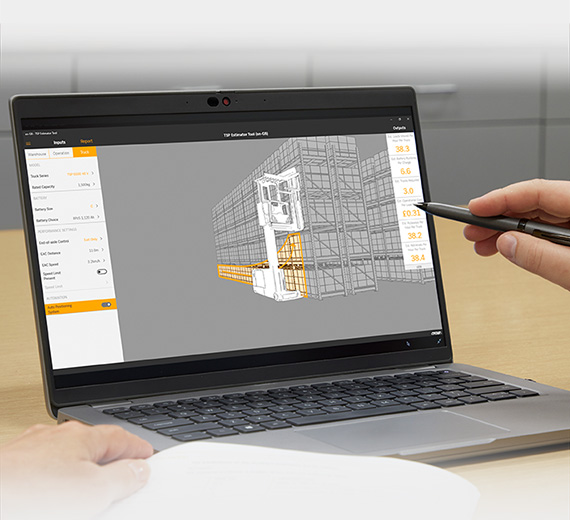

The Gena operating system provides operators with an intuitive, data-rich experience that's fully integrated into the VNA truck's architecture. Its 7'' touch screen is programmable in over 40 languages. Customisable widgets display key performance metrics.

The Capacity Data Monitor provides load weights, lift heights and capacity limits at a glance.

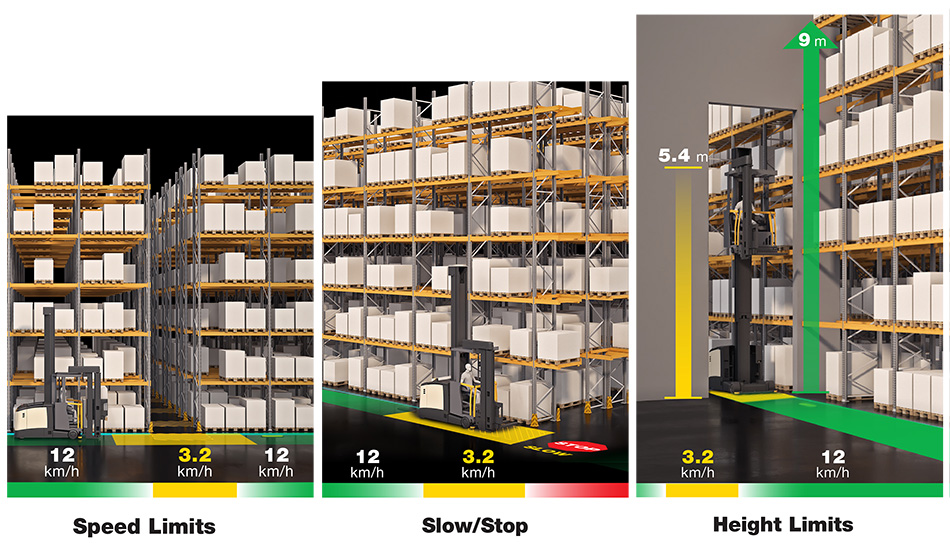

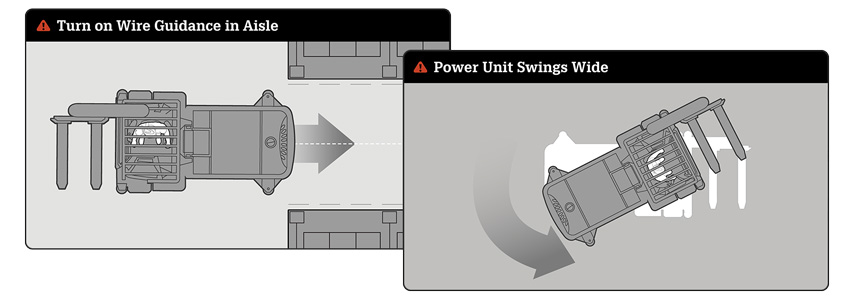

Colour-coded visuals are designed to alert the operator of current status, so they stay within specified load limits.

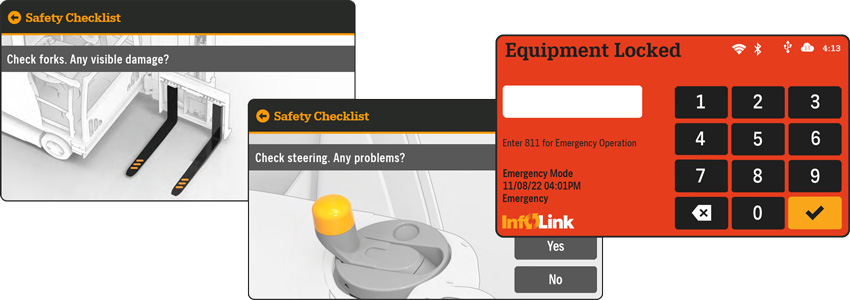

Crown's optional InfoLink Operator and Fleet Management System helps promote safe operating behaviour with features including access control, visual inspection checklists, impact detection and alerts, or equipment lockout. Real-time and historical data reveal areas of risk and identify areas of opportunity.

Upon log-in, the TSP Series displays safety messages to remind operators of their training.

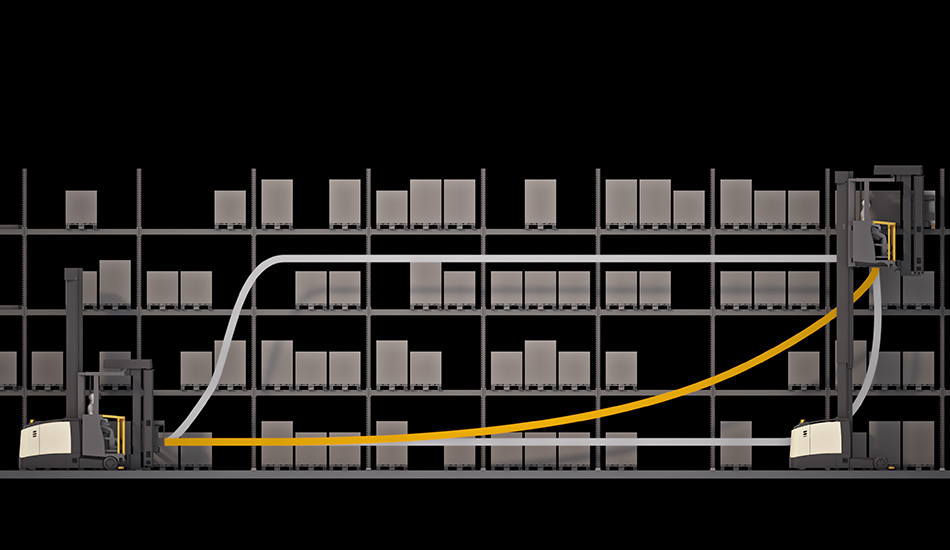

Clear interactive displays, automated assistance and coaching, and context-sensitive alerts further enhance performance and productivity.